Shurflo Pressure Switch for Pump: Full Handbook & Advice

Did you know the Shurflo Pump pressure switch usually deactivates at 55 psi yet can auto-prime up to 6 feet? Grasping how the Shurflo Water Pump pressure switch works is essential for everyone seeking to boost Water flow in recreational vehicles and diverse setups. This in-depth handbook provides RV enthusiasts, professionals, and home repair buffs with in-depth knowledge. It explains the pressure switch’s mechanics, calibration techniques, mounting methods, and upkeep suggestions. This Shurflo 2095 replacement data is vital whether you’re repairing a problem or enhancing your pump’s performance.

Essential Conclusions

- The pressure switch can shut off at 55 psi for optimum performance.

- It initiates bypass at 30 psi and completely opens at 65 psi.

- Watch out for overlapping pressures between bypass and shut-off to prevent errors.

- Its adjustable settings allow customization to match system requirements.

- Proper inlet performance demands at least 1/2” I.D. tubing.

- Thermal protection mechanisms avert damage by preventing overheating during dry operation.

- Adhere to the 20 minutes per hour intermittent use limit for optimal performance.

Comprehending the Shurflo Pressure Switch for Pump

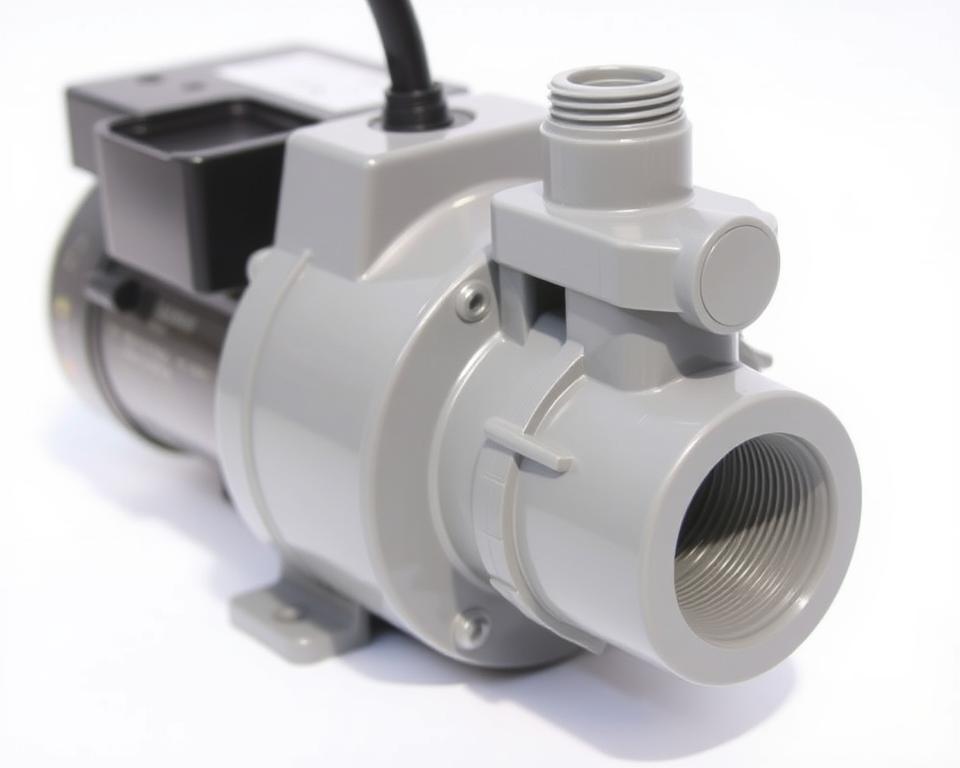

The Shurflo pump pressure switch is key in controlling Water flow for Pumps. It is engineered to facilitate liquid transfer, crucial for RVs and marine systems. We’ll explore its purpose, how it works, and its merits in detail.

Definition of the Shurflo Pump Pressure Switch

This pressure switch regulates Water system pressure by automatically controlling the Pump. It engages or disengages the pump based on pressure levels, ensuring constant Water flow and protecting the Pump from damage due to overuse.

How the Pressure Switch Works

The switch’s core duty is to observe Water pressure. It activates the pump if pressure falls, providing an uninterrupted supply. It deactivates the pump once optimal pressure is reached. This ensures a steady flow but also protects the pump from excessive use. You can adjust the settings to suit specific requirements.

Advantages of the Shurflo Pressure Switch

Opting for this pressure switch offers multiple advantages:

- Self-Operating Functionality: It ensures smooth pressure regulation through automated adjustments.

- Power Savings: Efficient operation minimizes energy usage by running the pump only as necessary.

- Reduced Wear: Minimizing operational stress lowers the risk of future damage and repairs.

- Consistent Pressure Control: Ensuring optimal pressure is key for reliable operation in mobile and stationary systems.

With its configurable features, this pressure switch meets diverse requirements, whether for shurflo 2095 replacements or other compatible parts.

Mounting and Setup Guidelines for Your Shurflo Pump

For your Shurflo pump and pressure switch to work best, install them properly. This means careful attention to mounting and plumbing is crucial. Such care minimizes potential installation errors.

Best Practices for Mounting

Mount the pump on a firm surface, within 6 feet of the Water tank, to maintain performance. Such positioning enhances accessibility and performance. For vertical installations, ensure the pump head points down to prevent fluid from leaking into the motor.

Using flexible high-pressure hose for the inlet and outlet ports reduces stress and noise and ensures smooth water delivery. Sharp tubing bends should be avoided as they may cause kinks and impede flow.

Important Plumbing Tips

The performance of the Shurflo pump pressure switch is closely linked to its plumbing setup. It’s crucial to use at least 1/2″ I.D. plumbing to stop cavitation. This avoids cavitation, which can cause high back pressure and low flow rates. Using a 50-mesh inlet strainer prevents debris from entering the pump.

Minimizing the use of elbows and valves in the plumbing reduces flow limitations. A streamlined plumbing configuration is crucial for maximizing pump efficiency.

Adjusting the Pressure Settings on Your Shurflo Pump

Adjusting your Shurflo pressure switch is crucial for its best performance. By calibrating correctly, you reduce the load on your pump and ensure efficient functioning. Start by finding the adjustment screw atop the pressure switch. This screw is key for adjusting the shut-off pressure settings.

Adjusting the Cut-off Point

Rotate the Allen screw clockwise to raise the shut-off pressure—this action increases sensitivity, leading to increased pump cycling. It boosts the shut-off pressure, ensuring the system maintains strong pressure. Conversely, rotating the screw counter-clockwise decreases sensitivity, reducing cycling.

Verify your changes by running a shower test—the pump should continue operating as water flows and stop when the shower is off. Make sure the shut-off pressure is maintained at least 10 PSI below the bypass activation threshold to avoid operational problems.

Understanding Bypass Settings

The bypass setting plays an essential role in protecting the switch while maintaining efficient operation. Adjusting correctly allows water to cycle from discharge back to the inlet at a set pressure. Right bypass settings uphold system efficiency. A bypass setting that is too high can cause the pump to remain active, risking harm.

Should these adjustments appear challenging, consider consulting an expert. Their expertise can prevent missteps and preserve your system’s integrity.

Resolving Typical Issues

Troubleshooting typical Shurflo pump issues necessitates recognizing various problems. Problems may arise from both electrical faults and physical component damage. Understanding these factors is essential for proper diagnosis and improved pump performance.

Non-starting Pump or Rapid Cycling Issues

If the pump fails to start, first inspect electrical connections. Ensure that fuses and switches are in working condition. If rapid cycling occurs, it might be due to air leaks or a malfunctioning strainer. Inspect both inlet and outlet valves for blockages that hinder operation. Fixing these pump pressure switch issues is vital for maintaining efficiency.

Faulty Pressure Switch Behavior

A defective pressure switch might inhibit pump activation or cause perpetual cycling. Verify the adjustment settings and clear any debris blocking the switch. Should problems continue, consider replacing the pressure switch. It’s vital to be vigilant about these shurflo switch issues for steady pump functioning.

Diagnosing Vibration and Noise Issues

Operational noise often signals issues such as loose fittings or improper installation. Ensure all connections are tightened and the pump is stably mounted to reduce noise. Flexible hoses may dampen vibrations, thereby lessening shurflo pump noise issues for a smoother performance.

Upkeep of Your Shurflo Pump Pressure Switch

Consistent maintenance is key to the optimal performance and longevity of your Shurflo pump. Upkeep involves cleaning, inspections, and proper winter preparation. Proper care enhances its performance and avoids future complications.

Cleaning the Strainer

Strainer maintenance is essential for keeping your Shurflo pump in top condition. Blockages from debris can disrupt performance. Regularly check and clean the strainer for best results. Keeping the strainer clean helps reduce operational stress on the pump.

Regular Inspection Tips

Routine examination of pump components is essential for early problem detection. Adopt a regular inspection schedule for:

- Wiring and connections for deterioration

- Tank fluid levels

- Tubing condition and secure fittings

- Performance of the pressure switch

Correcting loose fittings and checking switch performance enhances operation. Steady upkeep considerably increases the pump’s lifespan.

Pump Winterization Guidelines

Preparing your pump for winter is essential to avoid frost damage. For effective winterization:

- Fully empty the Water tank

- Purge the plumbing of residual Water

- Employ a non-toxic antifreeze to shield seals and components

These steps shield your system from cold damage and prevent costly fixes. Additionally, it ensures the system is set for the cold months ahead.

Essential Replacement Components for Shurflo Pumps

Maintaining your Shurflo pump system requires high-quality replacement parts. Key components from the Shurflo 2095 series are indispensable for system reliability. When replacing parts, consider essential items such as pressure switches, diaphragms, and valves. Only genuine Shurflo pump parts guarantee your system’s reliability and enhance its lifespan.

Overview of Shurflo 2095 Spare Parts

Shurflo 2095 replacement parts offer a range to meet diverse needs. Their seamless integration improves efficiency and minimizes issues. Each piece is crucial for maintaining the pump’s efficiency.

- Pressure switches: Regulate the activation cycles of the Pump

- Diaphragms: Maintain proper Water flow and prevent leaks

- Valves: Control pressure levels for smooth functioning

Where to Purchase Shurflo Replacement Parts

For those in search of Shurflo parts, Installation Parts Supply is a reliable supplier. They offer a full range of Shurflo pump components to meet every repair and upkeep requirement. Access to genuine replacement parts secures your pump’s performance.

In Summary

This pressure switch is central to ensuring consistent Water flow and longevity in various uses.

By grasping how it works, how to maintain it, and how to fix common problems, you can significantly enhance your Water system’s lifespan. This focus on maintenance can prevent common issues, boosting the Pump’s dependability, noted for its solid 4-year service streak.

Maintaining your Shurflo pump is made easy and cost-efficient with interchangeable parts for both the 12V and 24V models. Always verify part numbers—use 94-890-08 for the 12V and 94-890-09 for the 24V pressure switch to prevent unnecessary expenses and extend the pump’s longevity.

Evidently, well-maintained Shurflo pumps exhibit exceptional reliability. Expect enhanced performance from the latest models, reflecting the brand’s dedication to quality. For expert installation or trustworthy replacement parts, Installation Parts Supply is an invaluable ally. By following these maintenance tips, you secure years of reliable, efficient performance.